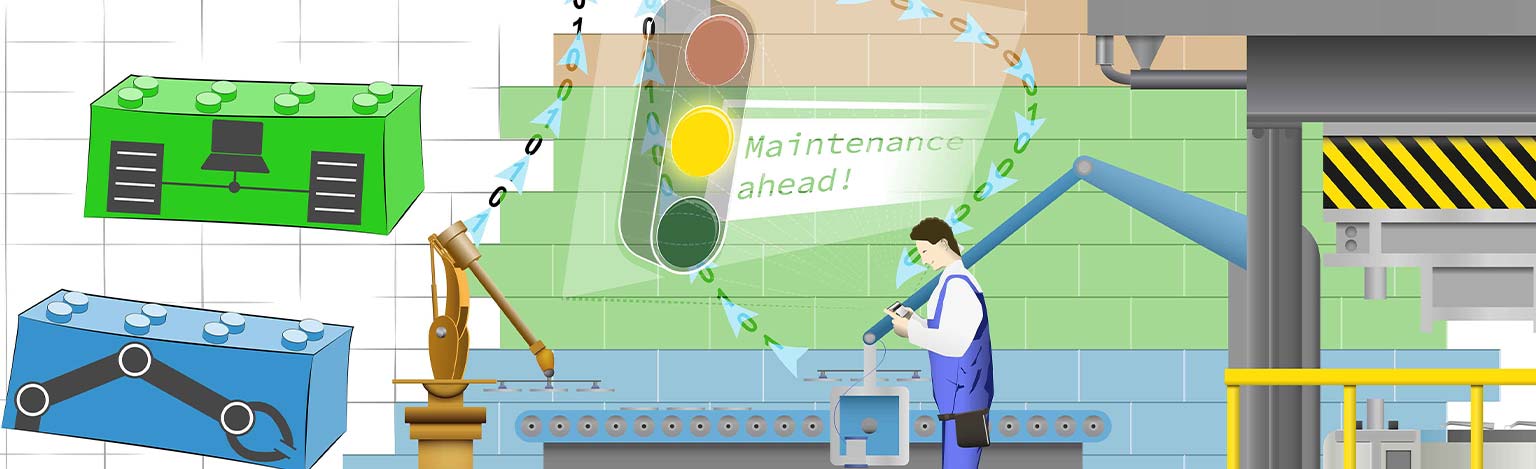

At international automotive supplier Benteler, the project involves systematically recording and evaluating machine data from a hydraulic press and a material conveyor system and deriving patterns in the production process. Using data-driven modeling methods and machine learning processes, machine faults, for example, can be detected long before they occur.

Based on the data obtained at Benteler, the Fraunhofer IEM is developing a process model for the introduction of intelligent maintenance. This requires a holistic view of all components and processes. In addition to the individual further development of data analysis methods, data sources such as sensors or machine data in production are systematically analyzed and enriched with expert knowledge, i.e. knowledge about the functioning and interaction of systems. These methods are then embedded in existing production and maintenance processes to support employees in the maintenance and inspection of machines and thus avoid operational failures.

The potential of the developed solution is huge: companies can use it to prevent malfunctions, better predict downtimes and make production management more efficient. For machine manufacturers, the data on their systems also provides valuable information for product optimization.

Fraunhofer Institute for Mechatronic Systems Design

Fraunhofer Institute for Mechatronic Systems Design