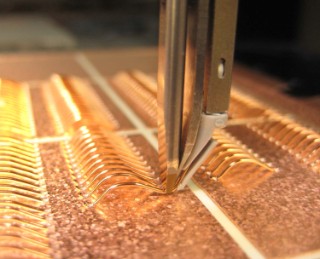

RoboGrinder: AI-based grinding system learns to process complex materials

Industrial project with düspohl

AI and control technology - a trustworthy combination.

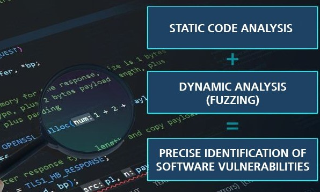

Working together with Düspohl, Fraunhofer IEM developed a novel grinding system incorporating AI-based software and, for the first time, automated a wholly manual production step at the mechanical engineering company. The robotic cell will autonomously learn how to grind the complex profile wrapping rollers. The RoboGrinder takes a hybrid approach to this challenge by combining powerful AI technologies with established control engineering methods. A machine learning module programmed specifically for the process also predicts any grinding errors. They are used to correct the basic control and enable the rubber-like rollers to be ground directly to size.

more info Fraunhofer Institute for Mechatronic Systems Design

Fraunhofer Institute for Mechatronic Systems Design