Mechatronic Testing Lab

Putting innovations to the test

Modern developments need to be tested under reproducible conditions. With the future-oriented inspection and testing technologies we have at our disposal in the Mechatronic Testing Lab, we can help you to bring your innovations to fruition. You will learn how to optimize your development processes as early as the design, integration and test phases using virtual subsystems and data-based methods.

Concept

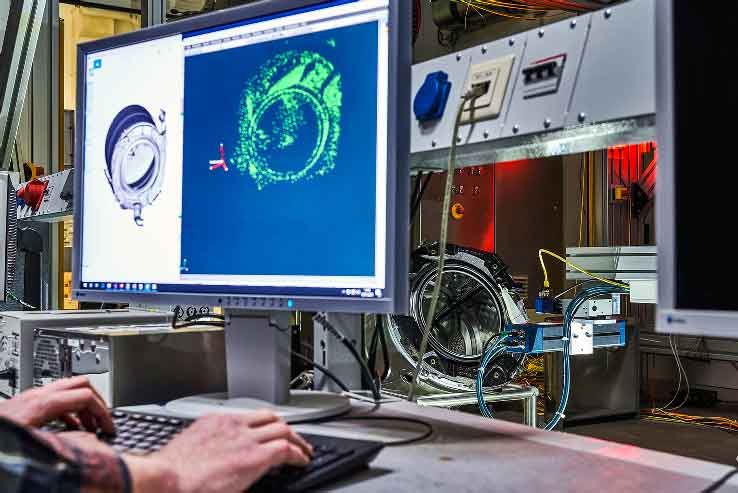

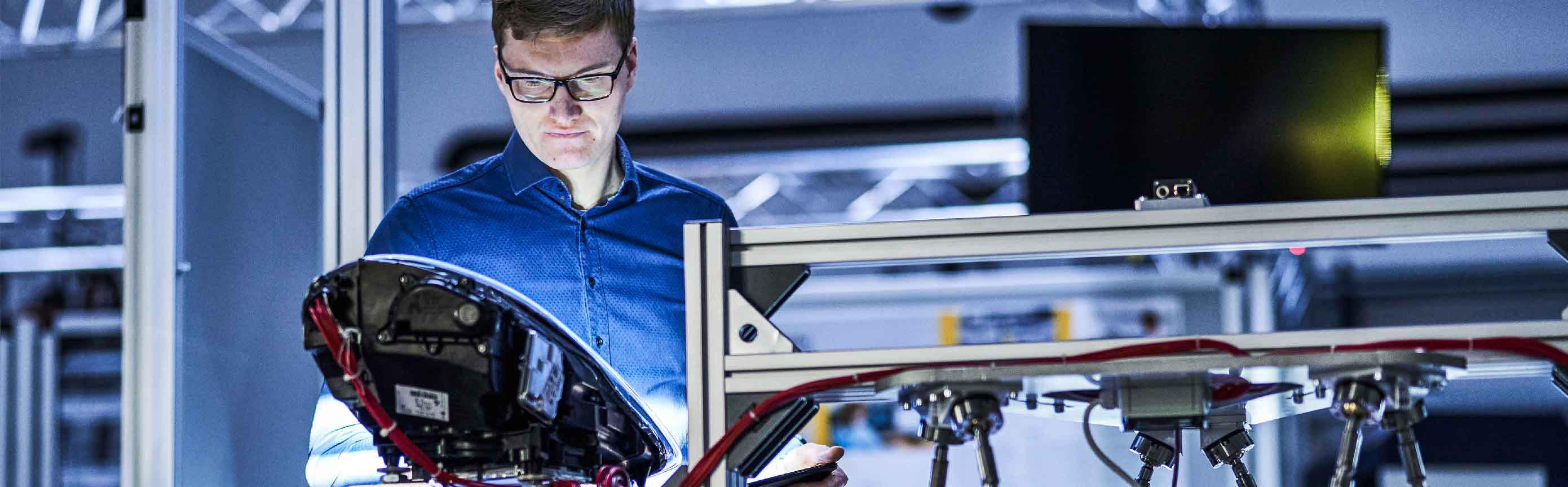

As a leading research institute, we are continuously looking at trends and new developments in the fields of automation technology, smart home, automotive and production technology. In the Mechatronic Testing Lab, we explore advanced testing methods in industrial and research projects and demonstrate the wide range of possible applications of X-in-the-Loop (XiL) technologies: We can demonstrate systems such as hardware-in-the-loop, rapid control prototyping or model-in-the-loop using an axle and headlight test bench, for example.

Target groups

The Mechatronic Testing Lab offers companies from the smart home and automotive sectors in particular a wide range of test procedures - along the entire value chain. In this way, processes and development work can be accelerated significantly. Companies such as Miele, Hella and numerous automotive suppliers have already placed their trust in our expertise. But potential applications are also opening up for other industries. In addition, the Mechatronic Testing Lab not only offers services for large and established companies, but also serves as an innovation platform for start-ups and small and medium-sized enterprises.

Service offering

The Mechatronic Testing Lab provides you with the ideal environment for implementing pilot tests and testing your new developments, products, systems and services. Take advantage of our infrastructure to conduct tests for new production methods before you implement them in your operations at great expense. For example, we offer testing of electrical and hydraulic components and systems for technical qualification, test new sensor and measurement technology and can provide you with automated test execution on a 24/7 basis. You can use our climate chamber for various environmental simulations. We also develop test bench concepts for all manner of electromechanical power steering and braking applications.

Here are some of the services we offer:

- Testing of initial control designs through rapid control prototyping

- Measurement and analysis of spring and damper components (hydraulic and electric) with an actuating force of up to 20.5 kN

- Hardware-in-the-loop testing for networked controllers, electric drives or automotive components

- Climate testing from 5–55°C with adjustable humidity

Take advantage of our expertise and the opportunity to work with state-of-the-art inspection and testing technologies. We can help you to strengthen your innovation capabilities, shorten the time-to-market of your products and services and launch new technologies. To take your team on this journey step by step, we also conduct customized training courses and workshops for your employees.

Fraunhofer Institute for Mechatronic Systems Design

Fraunhofer Institute for Mechatronic Systems Design