Why should companies be focusing on automation solutions right now in particular?

Christian Henke: Events like the global pandemic or current trade crises have naturally exposed the Achilles’ heel of many industries. We are currently working with many different companies to address the question of how we can use automation technology to meet the challenges of supply chain security, production resource optimization, and labor market shortages. At the same time, our solutions are also becoming more relevant to new industries like food technology.

Ansgar Trächtler: Another long-term challenge is the topic of sustainability and resource efficiency: in the future, companies will have to be able to provide reliable evidence regarding the carbon footprint created not only by their products, but by their entire value chain. For company strategies, this means that commercial success and public interest will be more closely linked than ever before. Business leaders must develop an awareness of the global and long-term effects of their commercial activities.

Automation technologies can also deliver solutions for tackling the challenge of sustainability. Are there any ongoing projects in this area?

Christian Henke: In the DENERGETIC project, we are working to develop an intelligent energy management system that will provide the answer to a key question: what is the best possible way to manage energy consumption across an entire residential area in terms of resource efficiency? A holistic approach is important here. The entire energy system, from suppliers to private households, must be considered as a whole.

Ansgar Trächtler: Basically, we enter into in-depth dialogues with companies about how they can integrate sustainability into their value creation chain. For example, we look at how they can design their products, materials and production processes in such a way that it’s possible to make repairs and switch out individual parts. We’re very interested in concepts such as digital green twins — together with HELLA, we want to research how energy requirements can be mapped during the product development phase and throughout the entire product life cycle.

Thinking more broadly, is the Scientific Automation research unit looking into any new fields of application?

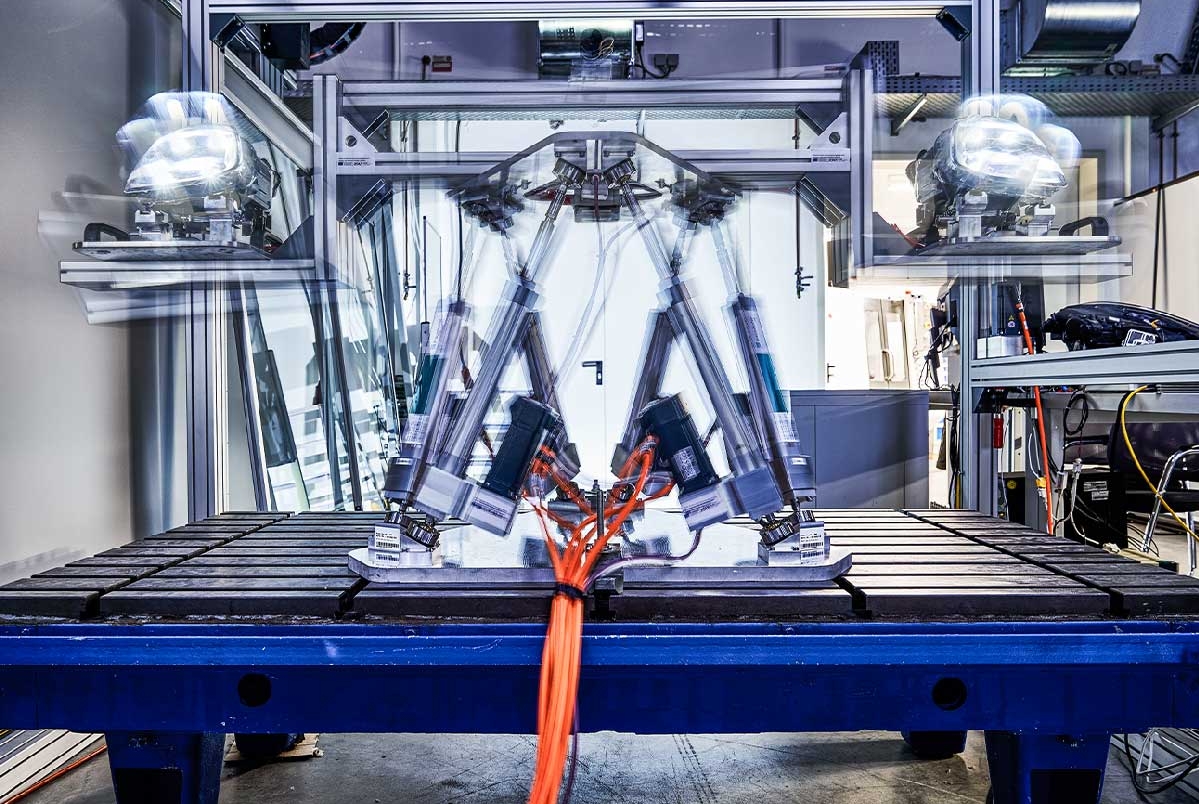

Christian Henke: Human-machine interaction is one area where numerous new fields of application are opening up — in the assistance and services sector, for example, or for personal care and applications in the private sphere. Our robotics solutions will enable flexible and resilient production systems. Other extremely exciting areas of research include robotics in construction and the combination of robotics and self-driving transport systems. As you can see, there’s a lot to do!

Fraunhofer Institute for Mechatronic Systems Design

Fraunhofer Institute for Mechatronic Systems Design